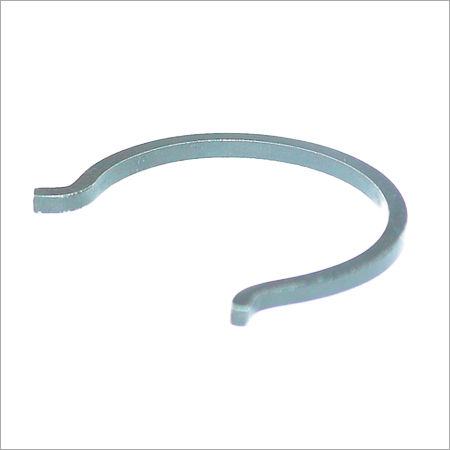

Retaining Ring

1 INR/Piece

Product Details:

- Grade 304,316

- Shape Round

- Material Stainless Steel

- Product Type Retaining Ring

- Application For Industry

- Click to View more

X

Retaining Ring Price And Quantity

- 5000 Piece

- 1 INR/Piece

Retaining Ring Product Specifications

- For Industry

- Retaining Ring

- Round

- 304,316

- Stainless Steel

Retaining Ring Trade Information

- 5000 Piece Per Day

- 45 Days

- Western Europe, Africa, South America, Australia, Asia, Middle East, North America, Eastern Europe, Central America

- All India

Product Description

With the strong assistance of our adept professionals, we are engrossed in manufacturing, exporting and supplying a large variety of Retaining Ring. Our highly qualified professionals utilize high quality raw materials and cutting-edge technology to manufacture this ring in sync with predefined industry standards. The offered ring finds its in large application in engines and machines. Also, clients can obtain this Retaining Ring from us in different designs and specifications at marginal prices.

Features ofRetaining Ring:

- Light weight

- Optimum performance

- Corrosion resistance

- High strength

Product details

|

Diameter |

0.5 - 10 mm |

|

Material |

Carbon steel |

|

Usage |

Automobile industry |

|

Surface finishing |

Oxidization or zinc-plating |

Durability and Corrosion Resistance

Our stainless steel retaining rings are constructed from grades 304 and 316, ensuring exceptional durability and corrosion resistance. This makes them ideal for use in environments where moisture, chemicals, or aggressive substances are present. The robust construction increases the service life of your machinery and reduces the need for frequent replacements.

Versatile Industrial Applications

Designed in a practical round shape, these rings are widely used across various industrial sectors in India, such as automotive, machinery manufacturing, and equipment assembly. Their adaptability to different shaft and bore sizes allows precise fitting and effective component retention, enhancing overall process reliability.

FAQs of Retaining Ring:

Q: How are stainless steel retaining rings installed in industrial equipment?

A: Stainless steel retaining rings are typically installed by compressing or expanding them into a groove on a shaft or inside a bore. This process secures the ring in place and ensures it holds components together within the equipment, preventing unwanted movement.Q: What advantages do grades 304 and 316 stainless steel retaining rings provide?

A: Grade 304 offers good corrosion resistance and mechanical strength, suitable for most industrial environments. Grade 316 contains molybdenum for enhanced resistance to chemicals and saltwater, making it ideal for harsher conditions or marine applications.Q: When should I use a round-shaped retaining ring in my industrial application?

A: Round-shaped retaining rings are best used when you need to fasten or locate components on cylindrical shafts or inside bores. They provide secure positioning and reliable retention, ensuring that parts remain in the intended location during operation.Q: Where can I source high-quality stainless steel retaining rings in India?

A: You can obtain premium stainless steel retaining rings from reputed exporters, manufacturers, and suppliers in India. These businesses specialize in providing industrial-grade components customized to your specification and application requirements.Q: What processes are involved in manufacturing stainless steel retaining rings?

A: Manufacturing retaining rings typically involves precision stamping or wire forming stainless steel into round shapes, followed by heat treatment and surface finishing. This ensures consistent quality, optimal strength, and corrosion resistance.Q: How do I benefit from using stainless steel retaining rings in my equipment?

A: Using stainless steel retaining rings helps enhance equipment reliability by securely positioning parts, reducing maintenance needs, and improving resistance to corrosion and wear. This translates into lower downtime and longer service life for your machinery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Rings' category

|

SPRING INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese