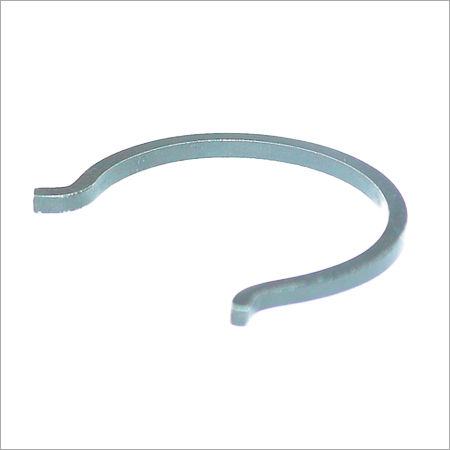

Snap Rings

5 INR/Piece

Product Details:

- Shape Round

- Surface Treatment Polishing

- Grade 304,316

- Usage Industrial

- Material Stainless Steel

- Size 0.5 - 10 mm

- Product Type Snap Rings

- Click to View more

X

Snap Rings Price And Quantity

- 5000 Piece

- 5 INR/Piece

Snap Rings Product Specifications

- 0.5 - 10 mm

- Polishing

- Industrial

- For Industry

- Round

- 304,316

- Snap Rings

- Stainless Steel

Snap Rings Trade Information

- Cash on Delivery (COD)

- 5000 Piece Per Day

- 45 Days

- All India

Product Description

Keeping the track of market development, we are able to manufacture, export and supply a broad variety of Snap Rings. These rings are precisely manufactured with the use of latest machinery and exceptional quality raw materials under the guidance of our technical experts. The offered rings are used in different industrial fittings. Moreover, our clients can easily get these Snap Rings as per their exact needs at market leading prices.

Features of Snap Rings:

- Compact design

- Resistant to rust

- Excellent tensile strength

- Accurate dimensions

Product details

|

Heat treatment |

HRC 47-54 |

|

Material |

Stainless Steel |

|

Diameter |

0.5 - 10 mm |

|

Surface finishing |

Oxidization or zinc-plating |

Robust Stainless Steel Build

Manufactured using high-grade 304 and 316 stainless steel, these snap rings deliver exceptional strength, wear, and corrosion resistance. Their reliable material properties ensure consistent performance in harsh industrial settings, benefiting manufacturers, suppliers, and end-users seeking longevity and minimal maintenance.

Versatile Industrial Applications

Available in a wide range of sizes (0.5 - 10 mm), our snap rings are well-suited to diverse industrial sectors. Their polished round design facilitates easy installation and removal, making them suitable for machinery assembly, automotive engineering, and heavy-duty equipment manufacturing.

Quality Assurance and Export Standards

As a leading exporter, manufacturer, and supplier based in India, our snap rings meet rigorous quality benchmarks. Each item undergoes careful inspection to uphold international standards, ensuring reliable performance and compatibility with global industrial requirements.

FAQ's of Snap Rings:

Q: How are these stainless steel snap rings used within industrial applications?

A: Our snap rings are primarily used as retaining rings to secure components onto shafts or within bores, preventing lateral movement. Common applications include machinery, automotive assemblies, and heavy equipment where secure fastening is critical.Q: What benefits do stainless steel grades 304 and 316 offer for snap rings?

A: Grades 304 and 316 stainless steel provide outstanding corrosion resistance, durability, and tensile strength. This makes our snap rings suitable for harsh environments, ensuring a longer service life and consistent reliability in industrial use.Q: When should I select polished snap rings for my equipment?

A: Polished snap rings are ideal when you require both aesthetic appeal and functional performance. The polished surface reduces friction during assembly and resists rust, making them best suited for visible or high-wear applications.Q: Where are these snap rings manufactured and supplied from?

A: Our snap rings are manufactured, supplied, and exported from India. With a broad distribution network, we serve clients domestically and internationally, ensuring timely delivery and dependable product quality.Q: What is the process involved in making these snap rings?

A: High-precision manufacturing techniques are employed, including stamping and heat treatment, followed by polishing to enhance surface finish. Each snap ring undergoes stringent quality checks to guarantee dimensional accuracy and structural integrity.Q: How do I choose the right snap ring size for my project?

A: Selecting the appropriate snap ring size depends on your shaft or bore diameter and groove dimensions. It's important to refer to your equipment's specifications or consult our technical team for guidance on sizing and compatibility.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Rings' category

|

SPRING INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese