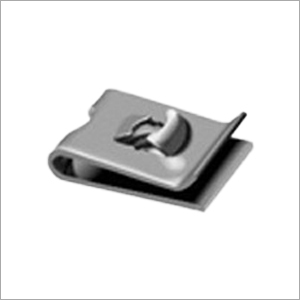

Spring Nut

2 INR/Piece

Product Details:

- Usage Industrial

- Material Stainless Steel

- Size M6, M8, M10, M12

- Product Type Spring Nut

- Weight 5-10 Grams (g)

- Surface Painted

- Color Sliver

- Click to View more

X

Spring Nut Price And Quantity

- 2 INR/Piece

- 5000 Piece

Spring Nut Product Specifications

- Painted

- 5-10 Grams (g)

- Sliver

- M6, M8, M10, M12

- Industrial

- Spring Nut

- Stainless Steel

Spring Nut Trade Information

- Cash on Delivery (COD)

- 5000 Piece Per Day

- 45 Days

- All India

Product Description

We a well-known manufacturer, exporter and supplier in the domain, engaged in offering excellent quality Spring Nut. This nut is extensively used to attach fittings to the open face of channels. Under our experts' direction, this nut is intricately designed and manufactured by utilizing high quality raw materials and high-end techniques in accordance with the set industry standards. Moreover, we provide this Spring Nut at pocket-friendly prices with no hassle. .

Features of Spring Nut:

- Corrosion resistance

- Robustness

- Easy installation

- Impeccable finish

Product details

|

Shape |

Rectangular |

|

Material |

Stainless steel |

|

Surface finishing |

Polished |

|

Size |

M6, M8, M10, M12 |

Precision Engineered for Industrial Needs

Built from stainless steel and treated with a painted finish, our Spring Nut is suitable for heavy-duty industrial environments. Its robust construction ensures stability under operational stress, making it ideal for high-performance and long-lasting fastening requirements. Choose from multiple metric sizes for a tailored solution to your project.

Trusted Manufacturing from India

With a strong reputation as an exporter and supplier, we prioritize stringent quality control and reliable delivery. Each Spring Nut is manufactured with precision in India using advanced processes, ensuring consistency, durability, and adherence to international standards. Our expertise supports industries worldwide, offering superior fastening solutions.

FAQ's of Spring Nut:

Q: How is the Spring Nut typically used in industrial applications?

A: The Spring Nut is designed for industrial settings, primarily for securing components to framing channels or metal structures. Its spring-loaded mechanism ensures quick, secure placement and reliable retention during assembly.Q: What are the benefits of choosing a stainless steel Spring Nut with a painted surface?

A: Stainless steel offers exceptional corrosion resistance, ensuring longevity even in harsh environments, while the painted surface adds an extra layer of protection and an attractive sliver finish, minimizing wear and tear.Q: When should I select between the different sizes: M6, M8, M10, and M12?

A: Choosing the right size depends on the specific bolt or channel size requirements in your application. M6, M8, M10, and M12 refer to the metric thread diameters-select the size that matches your equipment or design specifications for optimal performance.Q: Where are your Spring Nuts manufactured and supplied from?

A: All our Spring Nuts are produced in India at our advanced manufacturing facility. We export and supply these products both domestically and internationally, ensuring timely delivery and quality assurance to our customers.Q: What is the manufacturing process behind the Spring Nut?

A: Our Spring Nuts are manufactured using high-grade stainless steel. The process involves precision machining, forming the spring mechanism, applying a painted finish, and strict quality checks to ensure each nut meets industry standards.Q: What are the main advantages of using this product in industrial settings?

A: The primary advantages include fast installation, robust corrosion resistance, durable construction, and compatibility with a wide range of mounting systems. These features make our Spring Nut an efficient and cost-effective fastening solution for industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Captive Nut' category

|

SPRING INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese